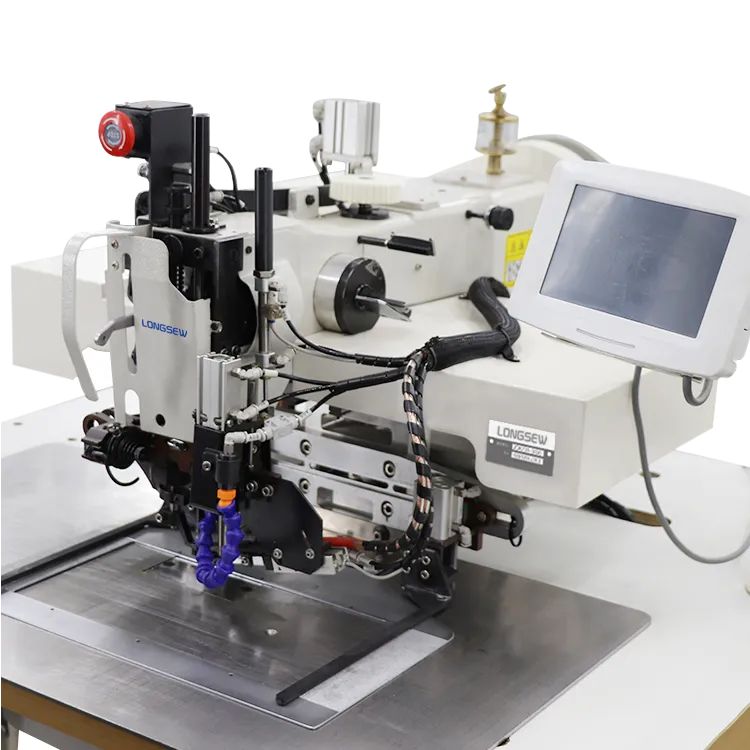

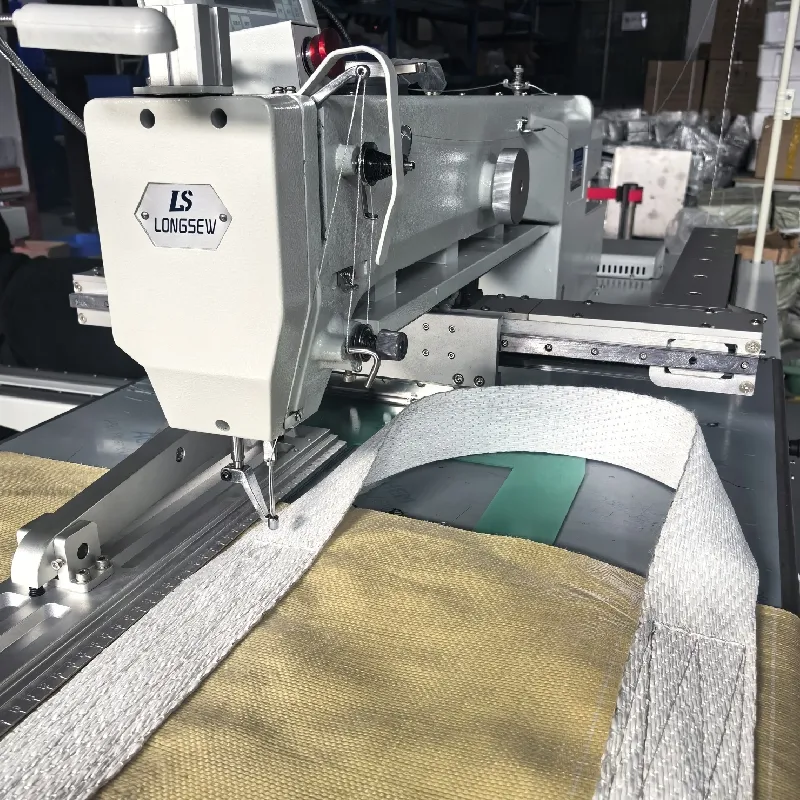

Sail making machine

Latest articles

The dressmaker deluxe zig zag sewing machine also makes it easy to add embellishments and decorations to garments. With a variety of built-in decorative stitches, dressmakers can easily create unique and eye-catching designs that set their creations apart from the rest.

Sail making machine...

Sail making machine 【Sail making machine】

Read More

...

Sail making machine 【Sail making machine】

Read More The Importance of Industrial Sewing Machines and Overlockers in Modern Textile Manufacturing

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreA compound feed heavy duty sewing machine is equipped with a unique feeding mechanism that combines different feed types needle feed, walking foot, and presser foot. This combination allows the machine to pull the fabric evenly from both the top and bottom, ensuring smooth stitching even on thick or multi-layered materials. This capability makes it ideal for sewing heavy fabrics such as leather, denim, canvas, and various synthetic materials.

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreIn conclusion, the rise in serger machine sales is a testament to the evolving landscape of sewing, driven by the DIY spirit and increasing interest in sustainable fashion. As consumers become more educated about their options, the market for these machines will continue to grow, offering exciting opportunities for both personal exploration and professional development in the world of sewing.

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreFinally, consider the size and weight of the machine. A heavy duty sewing machine should be sturdy and stable, with a large working area to accommodate big projects. Look for a machine that is built with a durable frame and has a wide table for ample workspace.

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreWhen considering the price of an automatic sewing machine, it is essential to factor in the additional costs associated with maintenance and repairs. Some machines may require specialized training or servicing, which can add to the overall cost of ownership. It is crucial to choose a machine from a reputable manufacturer that offers reliable customer support and warranty coverage

automatic sewing machine price.

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreAutomatic hand sewing machines are a type of machine that allows sewers to quickly and easily create various stitches and patterns without the need for manual labor. These machines are ideal for individuals who enjoy sewing but want to speed up the process and create more intricate designs.

Sail making machine...

Sail making machine 【Sail making machine】

Read MoreCleaning

Sail making machine

...

Sail making machine 【Sail making machine】

Read More

3. Quilting Needles Specifically designed for quilting, these needles have a tapered point that easily penetrates multiple layers of fabric.

5. Feed Mechanism A reliable feed mechanism is vital for smooth sewing, especially with heavier fabrics. Look for machines that have a strong feed dog system or an adjustable presser foot that can accommodate bulky materials.

what is a good heavy duty sewing machine

Conclusion

Moreover, the precision of automatic machinery minimizes errors in stitching, which can lead to defects and returns. As consumer expectations for quality continue to rise, manufacturers benefit from the reliability that these machines offer, ultimately enhancing brand reputation and customer satisfaction.

1. Robust Construction Built to withstand heavy use, these machines are often made from high-quality metals and components that ensure longevity. Their sturdy frames can handle the stress of sewing thick materials without compromising performance.

Links

Safety Considerations

When discussing high-pressure hoses, pressure ratings are crucial for their correct application. The percentages, such as 1% and 4%, refer to the hose’s ability to handle pressure in specific contexts.

Conclusion

Understanding Braided Hose Applications, Benefits, and Considerations

Common Applications

Key Considerations When Choosing a Hydraulic Hose Crimper

What is a Hydraulic Hose Crimper?

6. ตรวจสอบระบบเบรก ก่อนที่จะทำการทดสอบรถ ให้กดเบรกเพื่อตรวจสอบการตอบสนอง และดูว่าน้ำมันเบรกมีการรั่วไหลหรือไม่

- Cost Savings Although the initial investment in spiral wire hoses might be higher than standard hoses, their longevity and reduced need for maintenance can lead to significant cost savings over time.

Understanding Blue Air Hoses A Comprehensive Guide

Ultra high pressure hoses find applications in numerous industries due to their unique properties. Some of the most notable applications include

Conclusion

Өндөр даралтын шланга Гүйцэтгэл, хэрэглээ, ашиг тус

يمثل مصنع الخرطوم المضفر رمزًا للتفوق في صناعة الخراطيم. من خلال الابتكار والجودة العالية، يمكن لهذا المصنع تقديم منتجات تلبي متطلبات العملاء بأعلى مستوى من الأداء. لا شك أن الخرطوم المضفر سيظل عنصرًا أساسيًا في العديد من الصناعات، حيث يواصل المصنع تعزيز ثقافة الابتكار والجودة لضمان استمرار نجاحه في المستقبل.

Maintenance and Care

2. Flexibility Braided hoses are typically more flexible than rigid pipes or non-braided hoses, allowing for easier installation in tight spaces.

Recognizing the signs of a deteriorating brake hose is essential for vehicle safety. Common indicators include

At its core, a hydraulic hose hand crimper is designed to crimp the end of hydraulic hoses onto fittings. The process of crimping involves compressing the fitting onto the hose with a specific force, which creates a leak-proof seal. This is critical because hydraulic systems operate under high pressure, and any leakage can lead to system failure, safety hazards, and costly downtime.

High pressure propane lines are specifically designed to transport propane gas from storage tanks or delivery systems to end-use applications. These lines are constructed from materials that can withstand elevated pressures, typically ranging from 100 psi to several hundred psi, depending on the specific requirements of the system. Common materials used include carbon steel and specialized plastics, which provide durability and resistance to corrosion.

1. Type of Vehicle The make and model of your vehicle significantly affects the cost of brake hose replacement. Luxury or performance vehicles often come equipped with specialized parts that may be more expensive compared to standard models.

Hydraulic hoses are integral components of brake systems that require careful consideration regarding material, construction, and maintenance. By understanding their importance and adhering to correct selection and care practices, vehicle owners can ensure safe and effective braking performance, contributing to overall road safety.

The Importance of Silicone Intake Hoses in Automotive Applications

Silicone intake hoses have become increasingly popular in automotive applications ranging from everyday vehicles to high-performance race cars. In standard cars, they ensure reliable operation of the engine's intake system, contributing to optimal fuel efficiency and emissions control.

2. Flexibility A crucial aspect of any air hose is its ability to remain flexible in varying temperatures. Blue air hoses retain their flexibility even in cold conditions, preventing kinks that can disrupt airflow and lead to inefficiencies.

Hydraulic hoses are subject to wear and tear, making regular maintenance essential. Common issues include leaks caused by abrasions or cuts, bulging due to internal pressure, and degradation from exposure to various chemicals. If a hydraulic hose fails, it can lead to a sudden drop in power and efficiency, potentially causing delays and increased costs on a project.

The Role of Braided Automotive Hoses in Modern Vehicles

1. Leak Prevention Proper crimping creates a tight seal, reducing the risk of leaks under pressure. Leaks can lead to significant efficiency losses and create hazardous situations, especially in high-pressure environments.

Types of Steam Cleaner Hoses

The benefits of using spiral wire hoses are substantial, particularly when compared to traditional rubber hoses. Some of the key advantages include

Conclusion

- Construction Heavy machinery such as excavators, backhoes, and bulldozers rely on hydraulic hoses to operate effectively. These machines often require hoses that can endure the rigors of rugged environments while maintaining performance under high pressure.

An In-Depth Look at Air Hose Crimpers Essential Tools for Automotive and Industrial Applications

6. Inspect the Connection After crimping, visually inspect the fitting and hose to ensure that the crimp is even and secure. A poorly crimped connection can compromise the system's integrity.

Conclusion

Anwendungen in verschiedenen Industrien

Advantages of Wire Braided Flexible Hose

Eng muhimi, har bir haydovchi o‘z transport vositasining yoqilg‘i tizimini va u bilan bog‘liq shlanglar qanday ahvolda ekanini bilishi zarur. Xavfsizlikni ta'minlash va muammolarni oldini olish uchun muntazam ta'mirlash va teknologiyalardan foydalanish zarur. Shlanglarning egri va to‘g‘ri holatlarda ishlashini ta'minlash, transport vositalarining ishonchliligini oshiradi va haydovchi uchun xavfsizligini ta'minlaydi. Yuqorī bosim yoqilg‘i shlanglarining to‘g‘ri foydalanilishi va parvarishi hayotiy ahamiyatga ega va avtomobil mexanizmlarining uzluksiz ishlashini ta'minlaydi.

Factors Influencing Hose Selection

Understanding 3000 PSI Hydraulic Hoses An Essential Component for Modern Machinery

2. Reinforcement After extrusion, the hose is reinforced with layers of textile or wire mesh. This reinforcement is crucial as it helps the hose withstand the high pressures exerted by the hydraulic fluids. Depending on the application, different types of reinforcement can be used, such as braided steel wire or spiraled textile yarns, to enhance the strength and flexibility of the hose.

What is a Mobile Hose Crimper?

1% indicates that the hose’s internal diameter can vary by 1% from the nominal size, while 4% usually refers to the variability in how much pressure the hose can withstand without compromising safety. Choosing hoses with known tolerances is essential to avoid overpressure situations and potential hose failures.

- Precision and Consistency Hydraulic crimpers provide a uniform crimping force, ensuring that each connection is made to exact specifications. This reduces the risk of leaks and failures in hydraulic systems.

Choosing the Right Crimper

Applications of Hydraulic Oil Hoses

The Essential Guide to Steam Cleaner Hoses Versatility and Efficiency in Cleaning